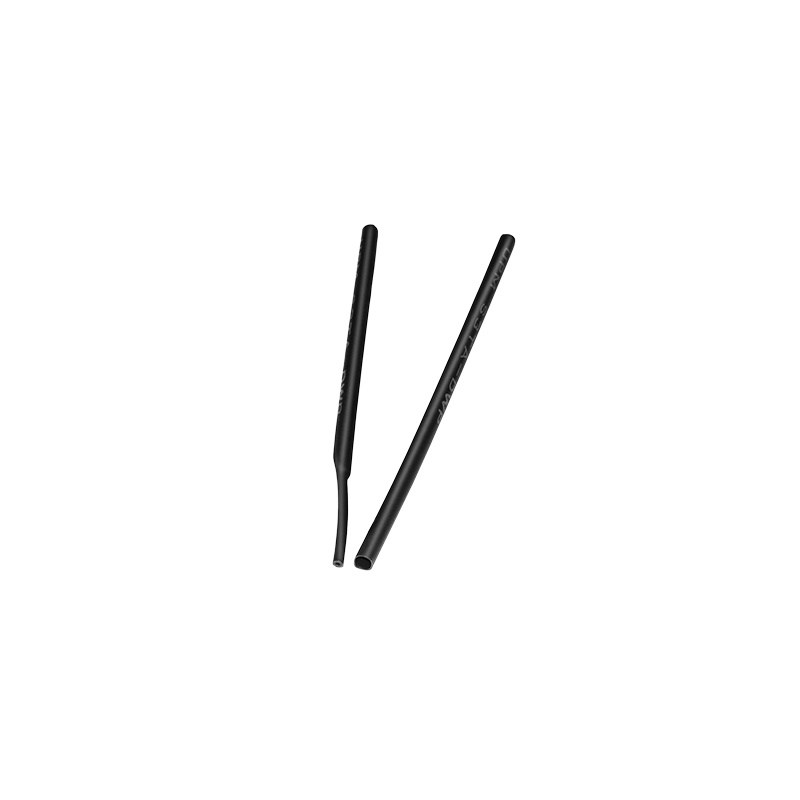

UPM HEAT SHRINK

关于我们

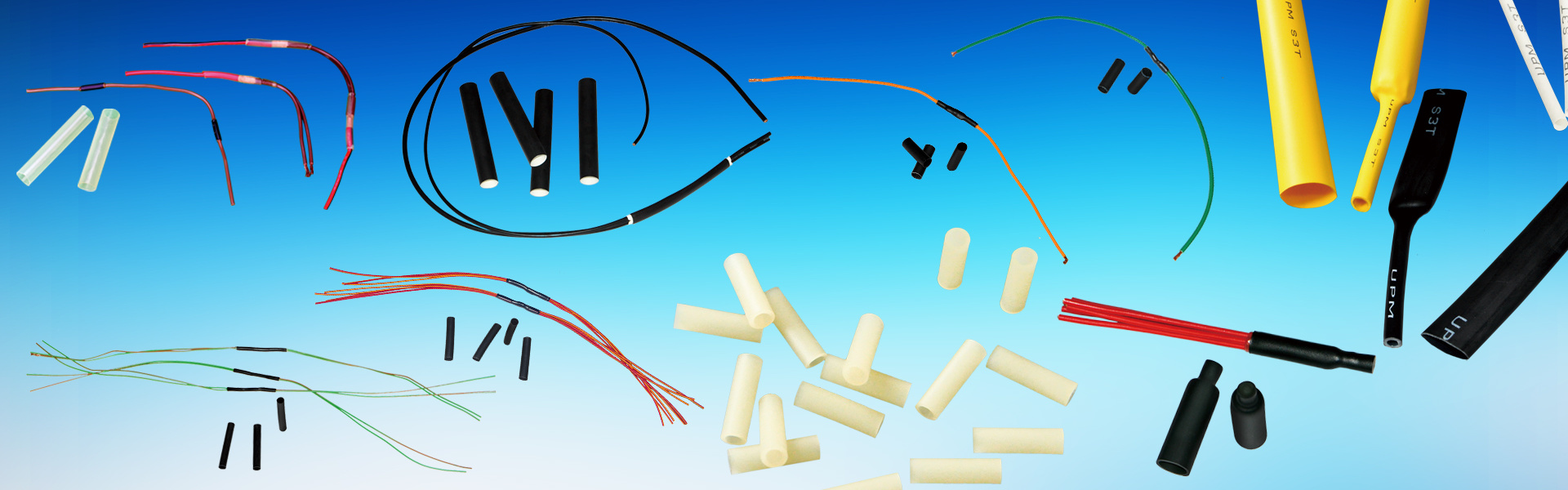

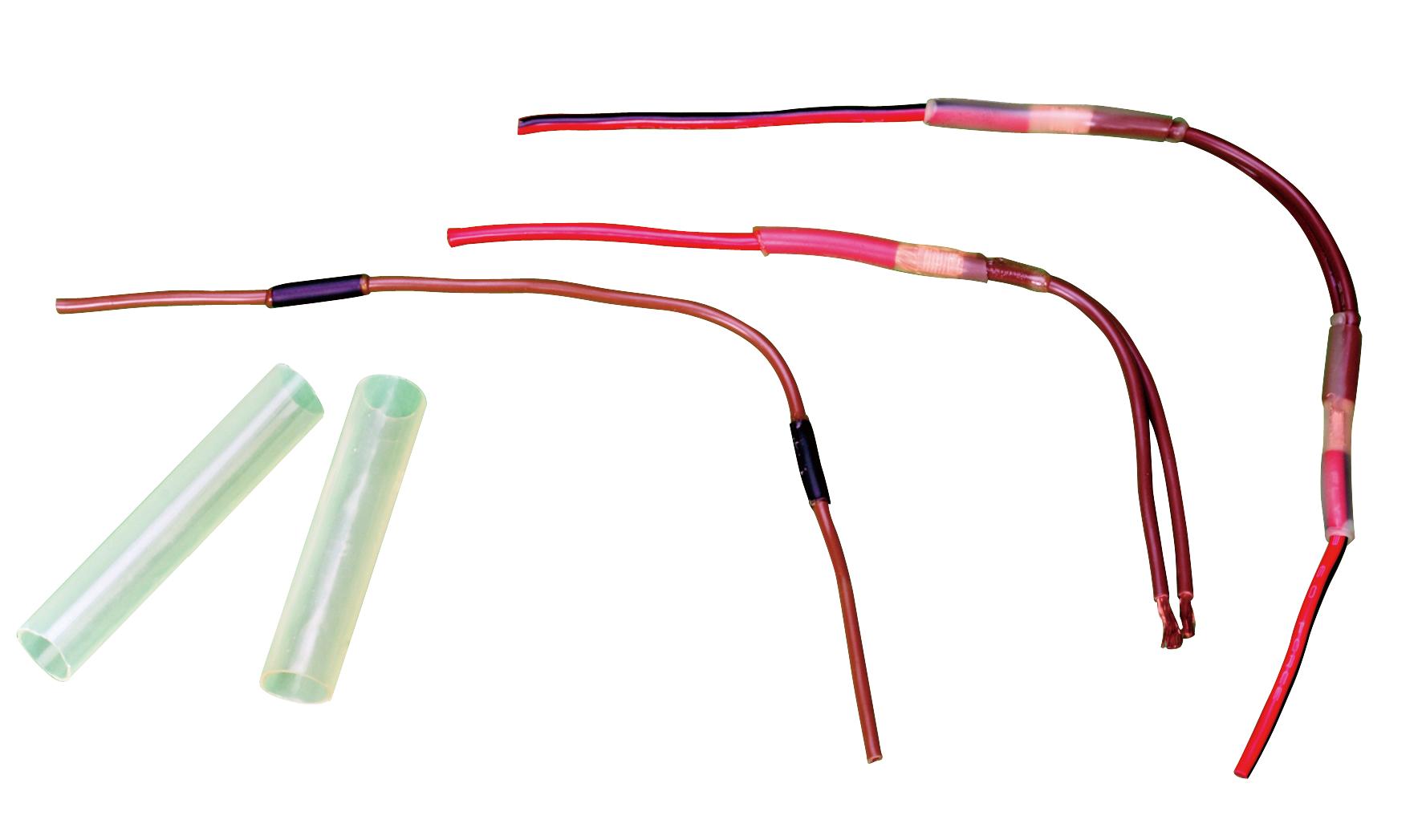

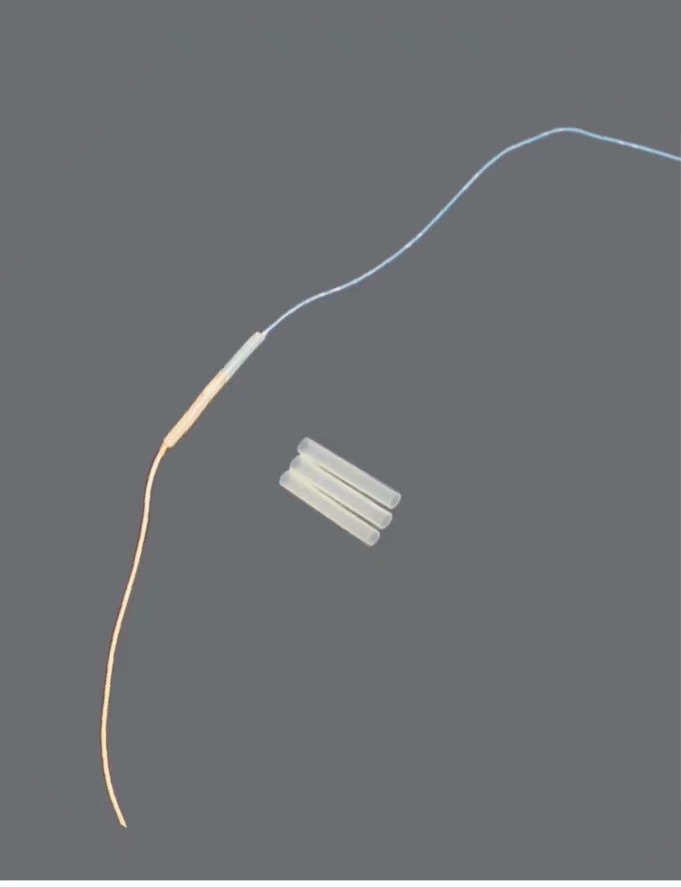

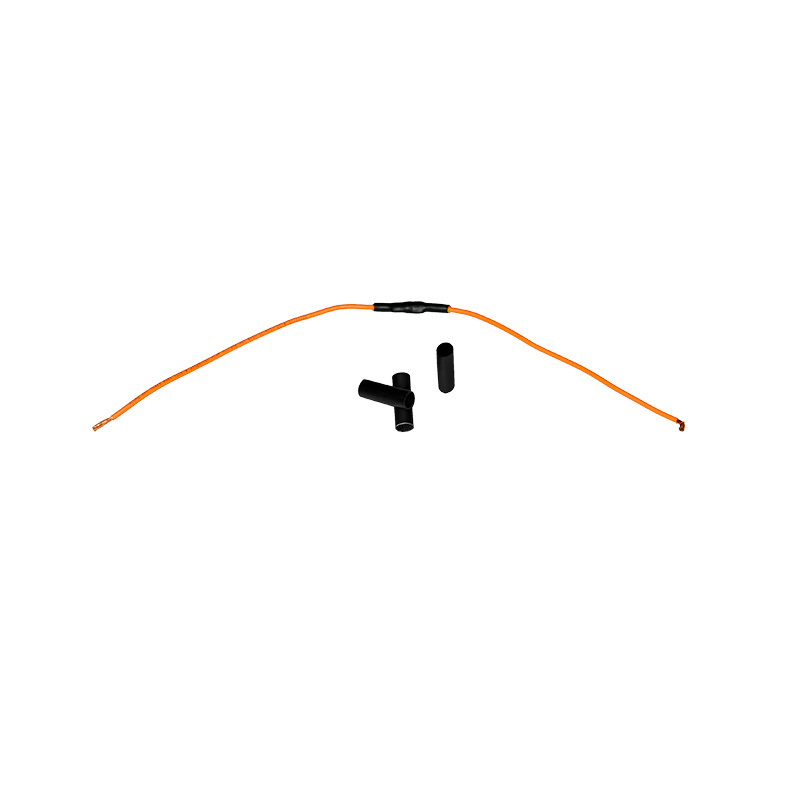

大连联合高分子材料有限公司(以下简称UPM),专业从事热收缩护套产品、编织护套产品及其它功能高分子材料的研发、生产和销售。专注提供系统零部件的覆盖保护解决方案,实现绝缘、防水、耐磨、抗冲击、束缚、捆扎、电磁屏蔽、标识等功用。产品主要应用于汽车、军工、航空航天、通讯、电力、电子、造船等领域。

UPM获得ISO 9001:2015,IATF 16949:2016,GJB 9001C-2017,ISO 14001:2015,ISO 45001:2018等质量、环境和职业健康管理体系认证。UPM产品通过或取得GJB,CE,UL,CCS,ABS,DNV等多项型式试验认可。

在本产品手册中,您将会了解我们目前产品的规格信息,技术参数等。我们会竭诚为您提供较优的解决方案,可根据客户需求定制产品,并不断研发新产品。

2002

成立于2002年,拥有20多年的行业经验

30000

m²

占地面积

90

%

能够自行完成90%以上的产品性能测试

应用行业

汽车

—

军工

—

造船

—

电力

—

电子

—

通信

—

行业解决方案

在不同领域均可以提供创新式的长效节能、长效防腐蚀解决方案

如果您想购买热缩产品,请随时与我们联系!

新闻中心

了解公司信息,掌握行业趋势