详细介绍

产品介绍

半刚性聚烯烃双壁热缩管,高收缩率,阻燃,适用于汽车线束电线接头、端子及组件的防水密封、绝缘防护;可定制长度。

产品特点

运行温度: -40℃至130℃

最小完全收缩温度: 135 ℃

环保,符合ELV,RoHS

收缩倍率: 4:1

颜色 : 黑色

技术参数

| 性能 | 检测方法 | 要求 |

| 热缩管性能 | ||

| 纵向长度变化 | ASTM D2671 | ≥-10% |

| 拉伸强度 | ASTM D2671 | ≥10.3MPa |

| 断裂伸长率 | ASTM D2671 | ≥250% |

| 2%割线模量 | ASTM D2671 | ≥137MPa |

| 热冲击(225℃/4h) | ASTM D2671 | 不滴不流无龟裂(外层) |

| 动态切割 | ASTM D3032 | ≥13.6kg |

| 体积电阻率 | ASTM D2671 | ≥1.0×1014Ω.cm |

| 阻燃性(仅外层) | ISO 6722-1 | 30S内自熄 |

| 接头性能 | ||

| 初始样品的漏电电流 | Q/DLH 0006 | ≤0.25μA |

| 室温反复弯折后 电流泄漏 |

Q/DLH 0006 | ≤0.25μA |

| 热冲击后 电流泄漏 |

Q/DLH 0006 | ≤0.25μA |

| 低温柔性 耐电压 |

Q/DLH 0006 1kV×1分钟 |

未击穿 |

| 耐溶剂后 电流泄漏 溶胀率 |

Q/DLH 0006 | ≤0.25μA ≤50% |

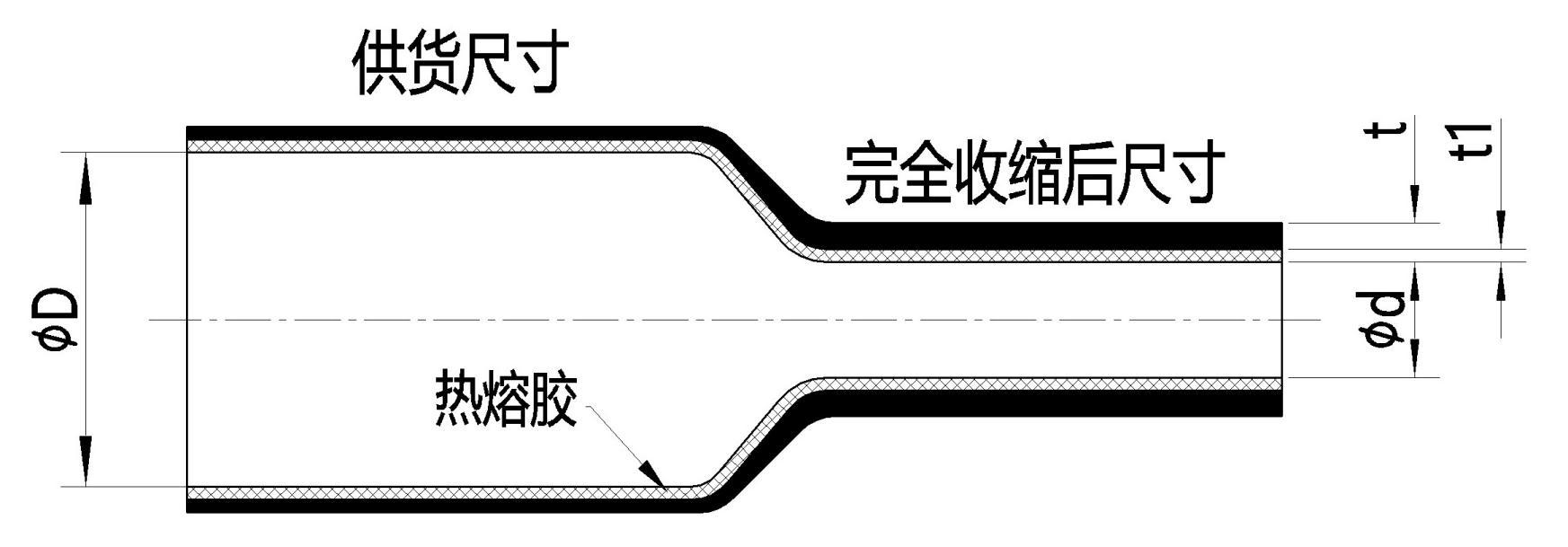

规格尺寸

| 规格 | 供货尺寸(mm) | 收缩后尺寸(mm) | ||

| A1 | 内径(最小) | 内径(最大) | 壁厚(参考) | 胶层厚(参考) |

| 4.0 | 4.0 | 1.00 | 1.00 | 0.50 |

| 5.75 | 5.75 | 1.25 | 1.20 | 0.60 |

| 7.5 | 7.5 | 1.65 | 1.60 | 0.80 |

| 9.0 | 9.0 | 2.30 | 1.80 | 0.90 |

| 11.0 | 11.0 | 2.40 | 2.00 | 1.00 |

| 14.0 | 14.0 | 3.00 | 2.20 | 1.20 |

| 18.3 | 18.3 | 4.45 | 2.40 | 1.40 |

产品对照

Tyco-Raychem: ES2000

产品图示

相关产品

在线留言