详细介绍

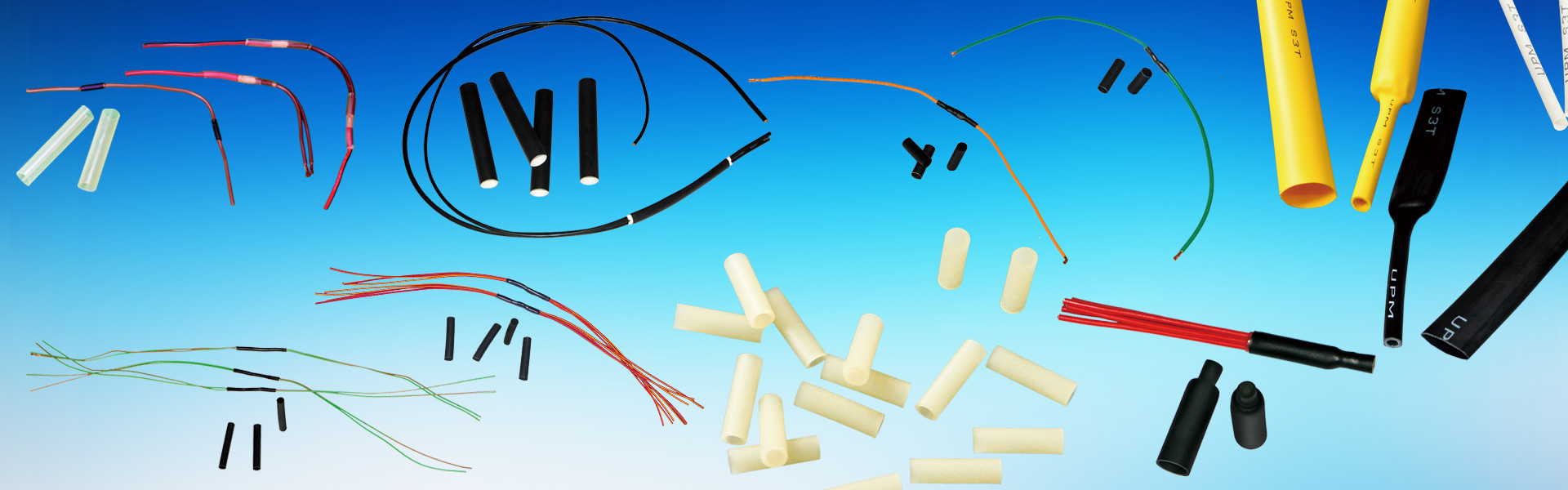

BTSP 裸纤保护套管

| 产品介绍 | |||

| 一种聚烯烃光纤保护热缩套管,专门为配线架/交接箱内裸光纤而设计的保护元件,形状多样,适合用于各种裸光纤 | |||

| 产品特点 |

| 运行温度: -55~100 ℃ |

| 最小完全收缩温度: 120 ℃ |

| 无卤,环保,符合RoHS |

| 标准颜色 :透明 |

| 技术参数 | ||

| 性能 | 检测方法 | 要求 |

| 拉伸强度 | ASTM D2671 | ≥16MPa |

| 断裂伸长率 | ASTM D2671 | ≥600% |

| 纵向长度变化 | ASTM D2671 | ±5% |

| 吸水率 (23℃/24小时) | ASTM D2671 | ≤0.2% |

| 低温柔韧性(-40℃/4小时) | ASTM D2671 | 无龟裂 |

| 击穿强度 | ASTM D2671 | ≥ 20kV/mm |

| 体积电阻率 | ASTM D2671 | ≥1.0×1014Ω·cm |

| 规格尺寸 | |||

| 产品选择 | 光纤(mm) | 形状 | |

| 尺寸D 或 H×L | 壁厚W | ||

| BTSP-1400 | 1.4 | 0.3 | 环形 |

| BTSP-2000 | 2.0 | 0.5 | 环形 |

| BTSP-3500 | 3.5 | 1.0 | 环形 |

| BTSP-2434 | 2.4×3.4 | 1.0 | 方形 |

| BTSP-3050 | 3.0×5.0 | 1.0 | 方形 |

相关产品

在线留言