详细介绍

WR-01N 环保焊锡环防水热缩中接端子

| 产品介绍 | |||

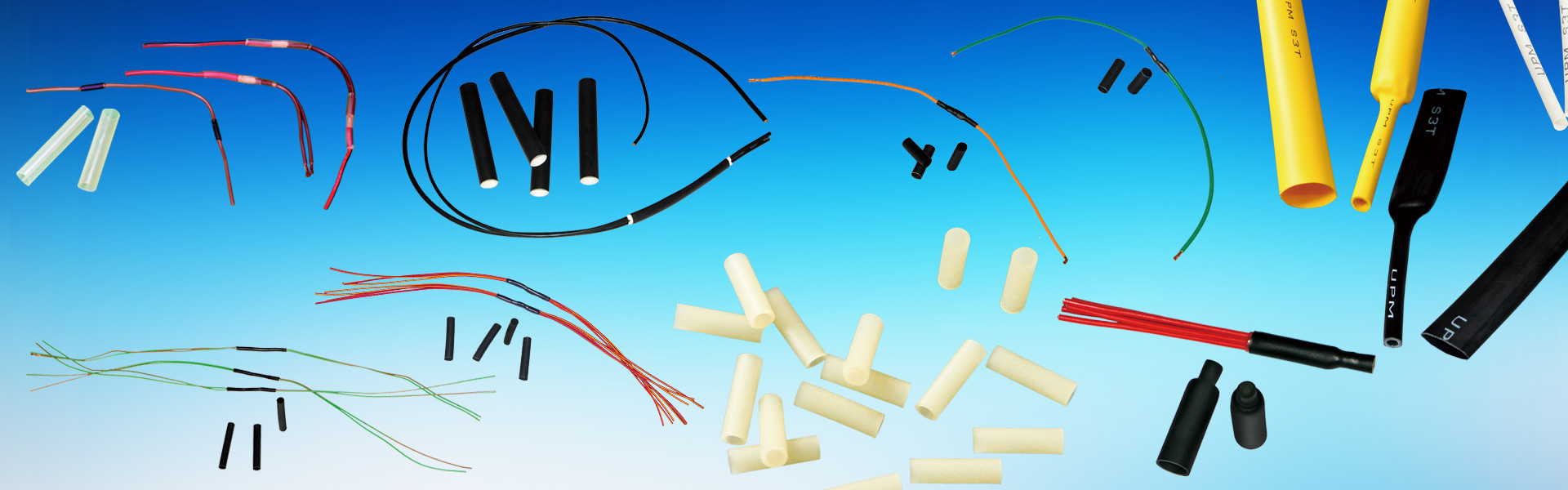

| 交联聚烯烃材质热缩管,内嵌无铅环保焊锡环和热熔胶环。透明设计,接线效果可视;胶环颜色区分尺寸,便于选用;无需压接工具,锡环受热熔接。用于导线连接,熔接、绝缘、防水一次性完成,安装简单方便。 | |||

| 产品特点 |

| 运行温度: -55~125 ℃ |

| 焊锡开始熔解温度:115℃ |

| 焊锡完全熔解温度:155℃ |

| 收缩倍率: 2:1 |

| 电压等级:600V |

| 无铅环保焊锡环 |

| 技术参数 | ||

| 产品性能 | 检测方法 | 要求 |

| 拉伸强度 | ASTM D2671 | ≥14MPa |

| 断裂伸长率 | ASTM D2671 | ≥400% |

| 老化后(150℃/168小时) 拉伸强度 断裂伸长率 |

ASTM D2671 |

≥10MPa ≥200% |

| 耐电压 | ASTM D2671 | AC 1kV·1min 无击穿 |

| 老化后(150℃/168小时) 耐电压 |

ASTM D2671 |

AC 1kV·1min 无击穿,且不低于老化前的50% |

| 低温柔韧性(-40℃/4小时) | ASTM D2671 | 无龟裂 |

| 热冲击(200℃/4小时) | ASTM D2671 | 无龟裂 |

| 2%割线模量 | ASTM D2671 | ≤250MPa |

| 体积电阻率 | ASTM D2671 | ≥1.0×1014Ω·cm |

| 规格尺寸 | ||||||||

| 零件号 | 产品尺寸(mm) | 包覆线径(mm) | 电线尺寸 | 颜色 | ||||

| 直径 | 长度 | B(min) | B&C(max) | C(min) | A.W.G | mm² | ||

| WR-01N-11 | 1.7 | 26 | 1.0 | 1.7 | 0.76 | 26-24 | 0.25-0.34 | 白色 |

| WR-01N-12 | 2.7 | 40 | 1.4 | 2.7 | 1.2 | 22-18 | 0.5-1.0 | 红色 |

| WR-01N-13 | 4.7 | 40 | 2.3 | 4.7 | 2.0 | 16-14 | 1.5-2.5 | 蓝色 |

| WR-01N-14 | 6.0 | 40 | 3.7 | 6.0 | 3.4 | 12-10 | 4.0-6.0 | 黄色 |

相关产品

在线留言